01. Drawings Received (Online Upload)

| 02. Part Analysis

| 03. What A DFM Covers For Metal Parts

| 04. What A DFM Covers For Plastic Parts

| 05. Customer Feedback And Final Sign Off

|

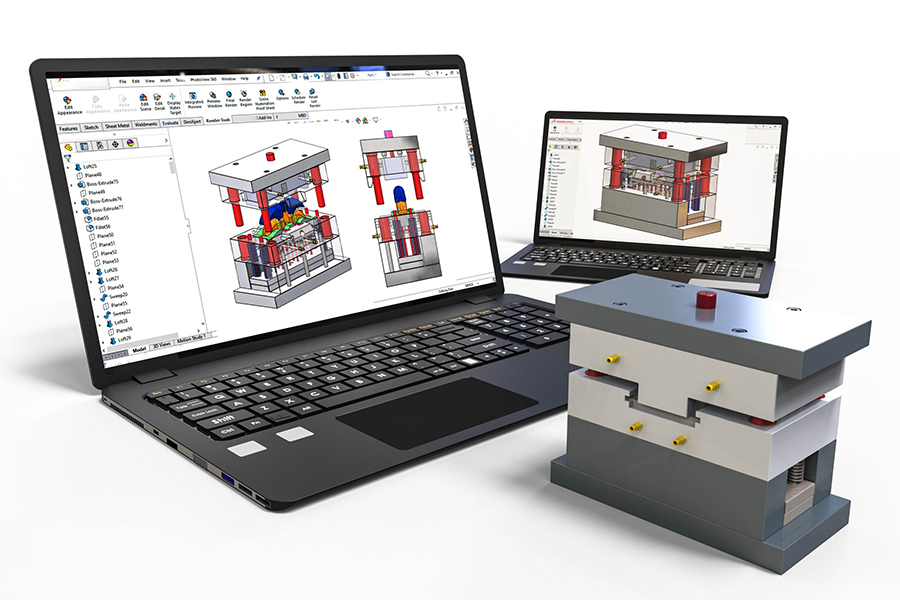

Tutamen utilizes expert in-house engineering expertise and advanced software systems to design with manufacturability in mind, streamlining your project's workflow and ensuring its successful and timely completion.

Our engineering capabilities include:

3D Part Scanning

Material Analysis Reports

3D Printing

Rapid Prototyping

Research & Development

Software systems we use include:

Master Cam

Pro E

Solidworks

Autodesk

Moldflow