STAGE 1: IN-LINE QC Operators are trained to inspect every piece as soon as it comes off our machines. An initial cosmetic check is followed up promptly by a dimensional check for any critical dimensions if necessary. | STAGE 2: CLEANING / FINAL QC / PACKAGING Once the part is finished production and any other finishing process, it goes to final QC / packaging. Here it is cleaned and inspected, and all critical dimensions and cosmetic standards are checked again. | STAGE 3: OUTGOING QC Once the part is finished production and any other finishing process, it goes to final QC / packaging. Here it is cleaned and inspected, and all critical dimensions and cosmetic standards are checked again. | STAGE 4: DATA COLLECTION / CPK Once the part is finished production and any other finishing process, it goes to final QC / packaging. Here it is cleaned and inspected, and all critical dimensions and cosmetic standards are checked again. |

Tutamen operates with high-standard clean rooms, ensuring that we can export market-ready products with the highest quality. By minimizing human contact and adhering to stringent cleaning protocols, we guarantee that all shipped goods consistently exceed quality expectations. Direct communication between inspectors and operators enables quick response times and efficient resolution of any issues. Additionally, our creative and innovative packaging solutions minimize post-production defects that could arise during shipping and handling.

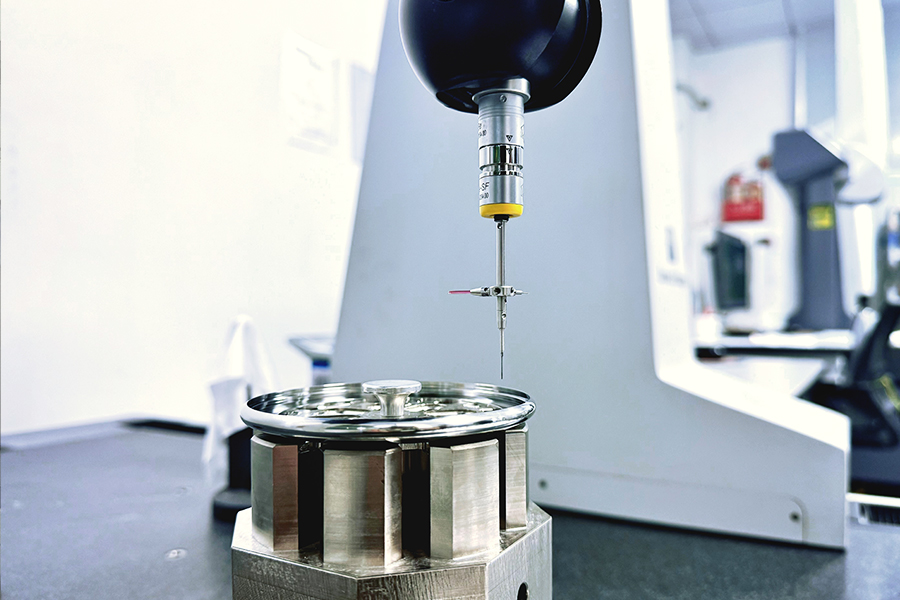

Our quality control department houses:

|

|

The final step in our process is assembly and finishing. From automated polishing machines to hand and robotic assembly, we ensure the highest quality standards and timely delivery by completing every aspect of our clients' projects in-house.

Our highly trained quality engineers work closely with the assembly team to ensure that the end products meet the expectations outlined at the project's inception. The team adheres to a strict Standard Inspection Procedure (SIP) and Standard Operating Procedure (SOP), maintaining both cosmetic and measurement standards.

With expertise in various finishing techniques—such as laser etching, pad and screen printing, anodizing, polishing, and sandblasting—Tutamen continuously refines and enhances the skills of our employees. This commitment enables us to deliver exceptional value to our clients today and in the future.